Neoprene

A synthetic rubber made by polymerization of chloroprene. Neoprene exhibits good chemical stability and maintains flexibility over a wide range of temperature. Neoprene foam is produced in either closed-cell or open-cell form. The closed-cell version is waterproof and used for wetsuits and drysuits. The foam is formed by injecting the neoprene with nitrogen gas, creating gas cells inside the material thus increasing its insulation properties.

Neoprene is produced in large blocks of material and cut to the required thickness, varying from 1mm to 10mm. The greater the thickness, the better the thermal insulation. To provide strength and protection, the foam can be laminated on either side with nylon, polyester or various other fabrics.

Due to its inherent structure, neoprene foam has a positive buoyancy. Since the foam largely contains gas pockets, the thickness and the buoyancy of the neoprene decrease at depth, loosing some of its thermal insulation.

The quality of the neoprene depends on the foam used and the density of the material. The amount of gas cells and their size is directly related to the durability of the foam. A denser neoprene will be more durable, less buoyant and resist better to the great ambient pressure at depth.

YAMAMOTO: Limestone Based Neoprene In an effort to provide the perfect material to its customer, SF Tech is using the best neoprene available on the market. A Japanese neoprene foam made at 99.7% of Limestone, (calcium carbonate) making it more environment-friendly than petroleum-based products. We use only #88 neoprene, a high-density hyper-compressed neoprene foam with excellent thermal insulation, exceptional durability and can withstand high pressure without loosing its properties.

Trilaminate

The term trilaminate means a multi-layered material composed of three layers of overlapping materials, laminated together. An inner and outer linings provide the strength and durability whereas the middle layer ensure the watertightness of the material.

The impermeable material is made of butyl rubber and is just a few tenth of millimeter thick. To avoid tearing and ripping, an outer protective fabric is necessary. Usually, a strong, non-elastic woven material (Nylon, Polyester, DuPont™ Kevlar®,…)

Due to its minimal thickness, trilam does not provide any thermal insulation. Therefore, the diver must use appropriate undergarment, generally thicker than with a neoprene drysuit. However, the buoyancy of the material is reduced and the material is drying faster.

Despite the many technological advances and material improvements, the name Trilam stayed and now encompass various materials made from 2 (bi-laminate) up to 8 (octo-laminate) layers.

Technically speaking, as describe above, neoprene is a trilaminate material where the middle liner is made of neoprene. But to avoid confusion, both technical terms, Neoprene and Trialm, are used to describe the categories of products.

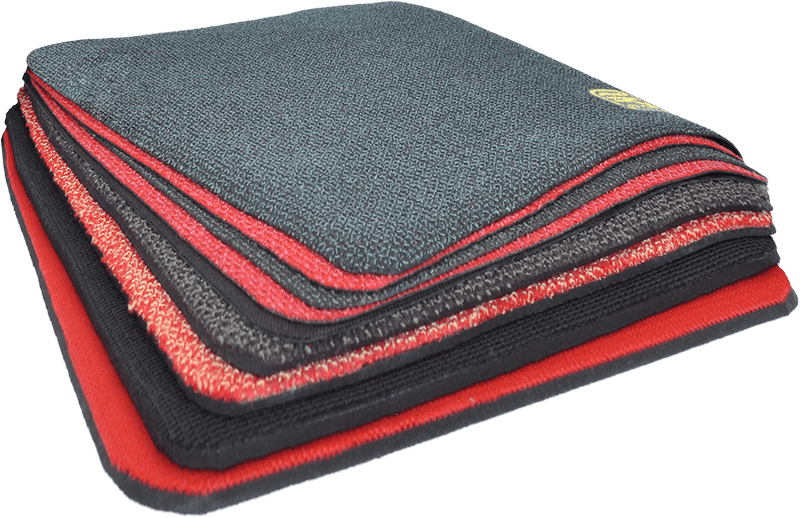

tnt

Revolutionary material invented and developed in the premises of SF Tech, TNT is a trilaminate material using high density neoprene foam as an impermeable layer instead of butyl rubber.

The initial fabrication process of the TNT is the same as a neoprene material. A layer of neoprene foam is laminated with an inner and outer layer. Then, the overall material undergoes a second compression phase in a hyperbaric chamber. This process creates a thin, flexible, ultra-dense neoprene trilaminate. By using neoprene as a impermeable medium instead of butyl, flexibility and heat retaining property are drastically improved, with an increase of heat insulation up to 40%.

To further improve the thermal isolation of the material, a coating of solid Titanium alloy, called Ti-Alpha, is applied directly on either side of the neoprene sheet, creating an efficient insulating barrier. The exterior layer reduces cold absorption and the interior layer increases heat reflection, keeping the warm body temperature inside the suit. By reducing heat exchange and acting as a reflective barrier, the titanium significantly improve thermal insulation up to 40%.

By combining the heat properties of the neoprene and the reflective layers of Titanium, TNT drysuit feels nearly twice as warm as a corresponding butyl trilaminate drysuit.

As with our butyl trilaminate, state of the art textiles are used on our TNT. The outer layer is exactly the same and consist of DuPont™ Kevlar® reinforced Nylon and Polyester, whereas the inner layer is made of Nylon.

polartec

Polartec® Power Stretch® has the ability to retain warmth without restricting movement or agility during activities. The outer surface has a low-friction finish that reduces irritation when worn with other fabrics and increases overall abrasion resistance. The next-to-skin layer stays dry, breathable and comfortable by continuously transferring moisture vapor for rapid evaporation. Reinforced elastic fibers ensure the fabric consistently rebounds after every stretch.

This versatility provides flexible support and warmth for reliable comfort in any sport based activity. Polartec® wicks moisture like a base material, but can handle direct exposure to the elements when necessary.

Odor resistant: Garments stay fresher for longer between washes. A silver chloride treatment inhibits the growth of odor causing bacteria for the life of the garment

Durable water repellent: Greatly increases the fabric’s inherent ability to resist water and snow without sacrificing breathability

Hardface: Dramatically increases abrasion resistance, reduces surface friction against other layers and adds durable water repellency

Recycled with Repreve®: Fabric contains a minimum of 50% Repreve® recycled fibers that conserve energy and reduce CO2 emissions

Easy care: Polartec® fabrics are known for their easy care and lasting durability. Most Polartec® fabric can be washed in warm water and tumbled dry on low and in most cases this will deliver the best post-wash feel and performance